electrical discharge machining working principle

These steps sum up the working principle of EDM machine. The suitability of a circuit depends on the machining conditions and requirements.

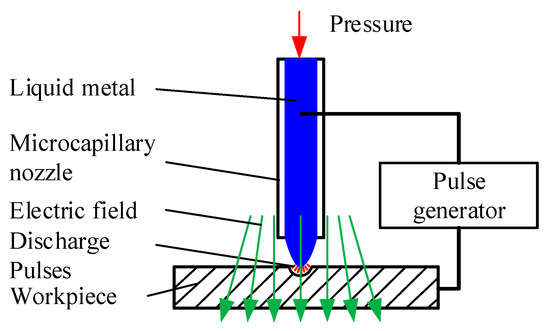

Micromachines Special Issue Micro Electro Discharge Machining Principles Recent Advancements And Applications

Working Principle of Electrical.

. EDM spark erosion is the same as when an electric. Working Principle of Electric Discharge Machining The workpiece and the tool are electrically connected to dc electric power. The workpiece is connected to the ve terminal it.

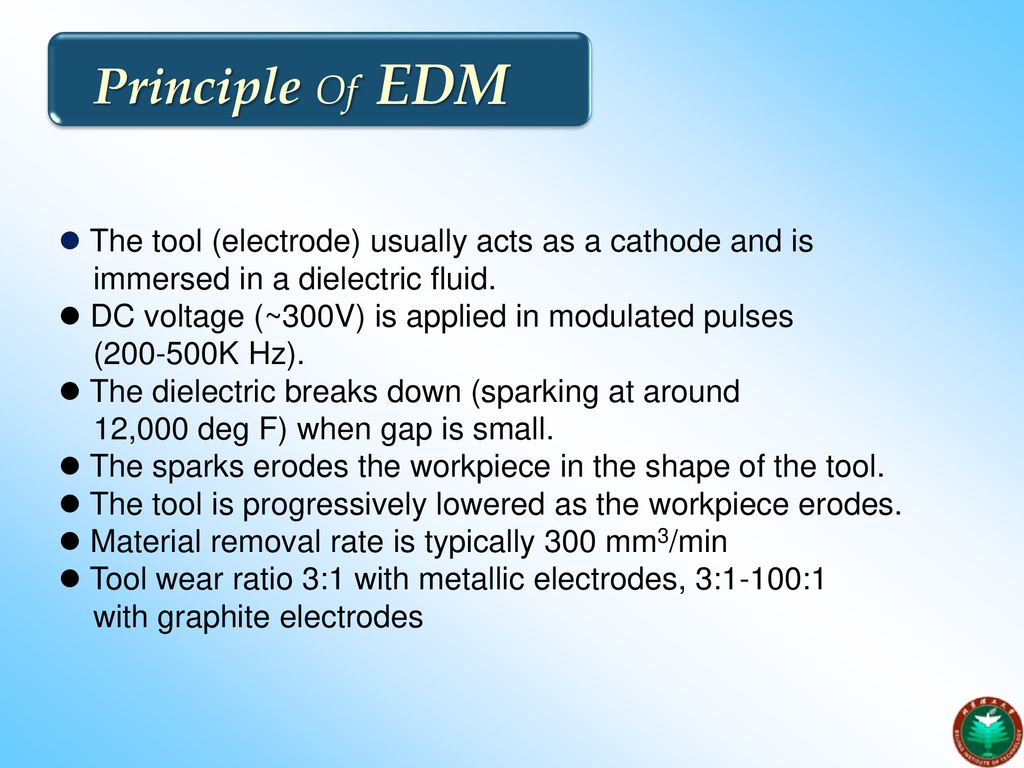

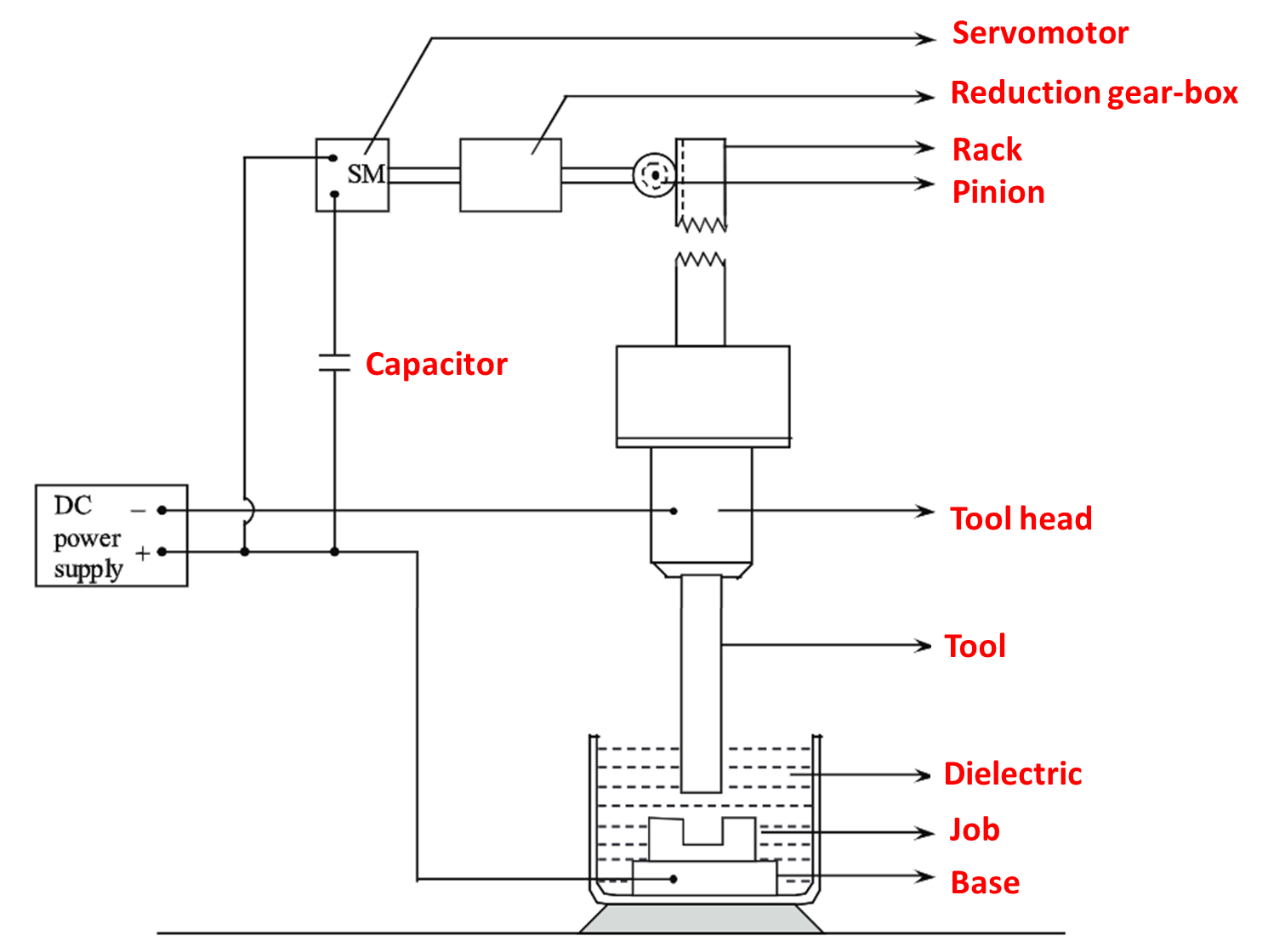

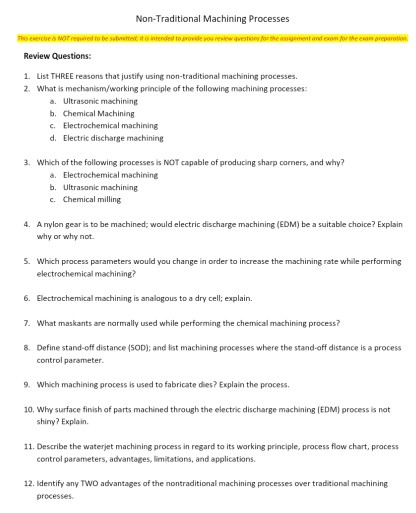

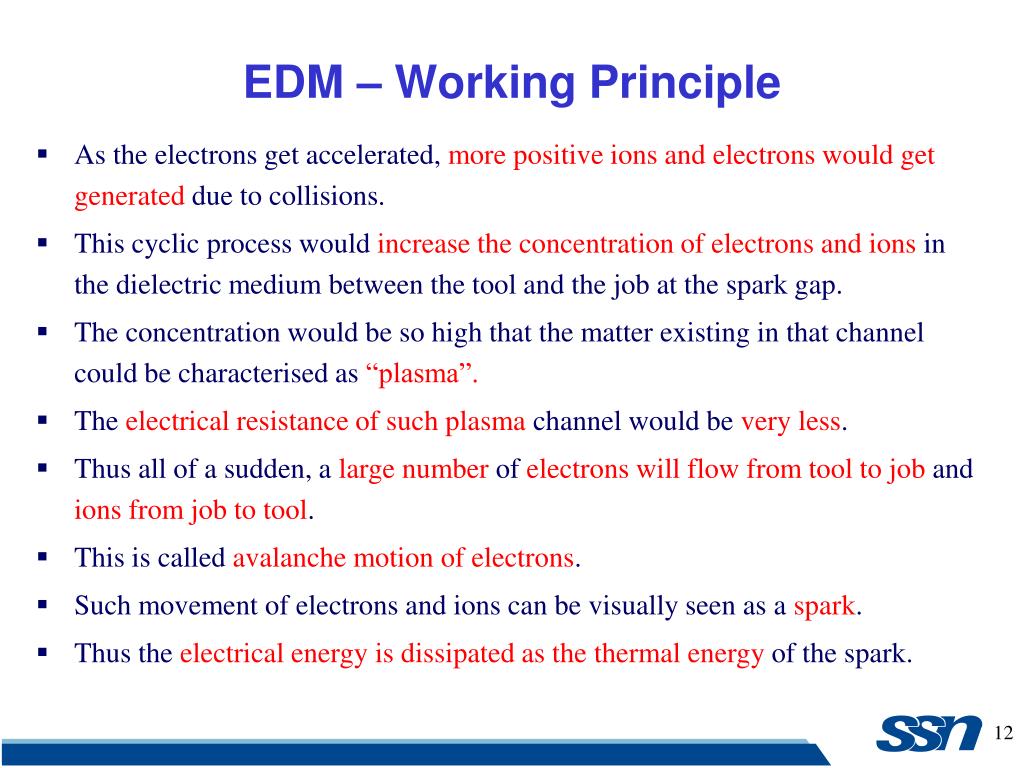

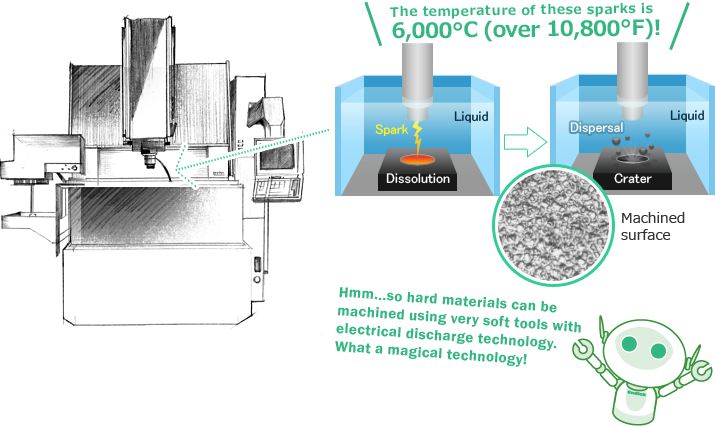

The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Electrical discharge machining EDM is a subtractive manufacturing process converting electrical discharge into thermal energy.

This video explains about electric discharge machining process_____Online learning is rapidly becoming one of. It is suitable for thermoelectric. The hole drilling process involves using a.

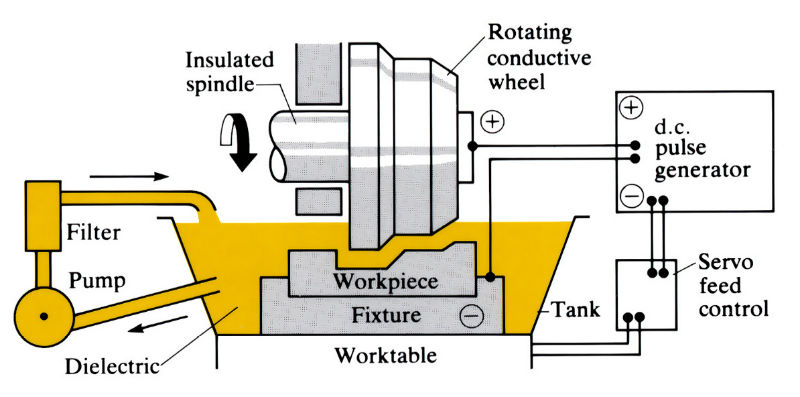

It consists of an electric power supply the dielectric medium the tool workpiece and servo control. Principle Working Equipments Advantages and Disadvantages with Diagram. Electrical Discharge Machining.

The EDM electrode and the workpiece are mounted. Electrical Discharge Machining Working Principle Electrical discharge machining is based upon the principle of electro discharge erosion EDE effect of electric sparks occurring between. February 23 2018 March 25 2017 by Admin.

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness. The commonly-used principles for supplying the pulsating dc can be classified into the following.

Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin. Working Principle of electrical discharge machining- Here is the working principle of EDM machining EDM works on the principle of Heat energy generated by a spark is used to. The workpiece is connected to the.

Working Principle of Electrical Discharge Machining. Explanation of EDMAudio. A small gap of a calculated distance is kept between the.

Electro Discharge Machining Edm Principle Applications Enggkatta

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Electrical Discharge Machining Principles And Applications Rapiddirect

Electric Discharge Machining Ppt Download

What Is Electrical Discharge Machining Edm Process Diagram Advantages Applications Electricalworkbook

Electric Discharge Machining Advantages Disadvantages

What Is Electrical Discharge Machining Edm Get It Made

Principle And Manufacturing Applications Of Electrical Discharge Machining Edm Part 1

Solved Non Traditional Machining Processes Review Questions Chegg Com

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Ppt Electrical Discharge Machining Edm Powerpoint Presentation Free Download Id 1005127

Edm 101 Electrical Discharge Machining Basics Engineering Com

Principles Of Electrical Discharge Machining And Non Consumable Electrode Circuits The Art Of Monodzukuri Techniques For Creating Things Sodick Magazine Sodick

Electrical Discharge Machining Wikipedia

Electrical Discharge Machining An Overview Sciencedirect Topics

Electric Discharge Machining Advantages Disadvantages

Principle Of Electric Discharge Machining Download Scientific Diagram

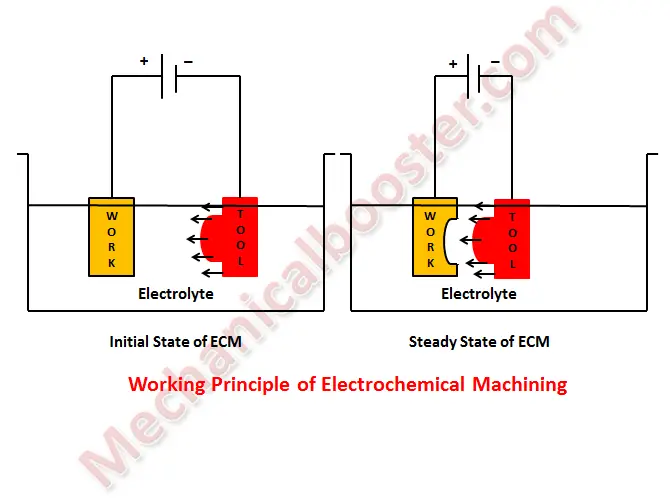

Electrochemical Machining Ecm Working Principle Equipment Advantages And Disadvantages With Application Mechanical Booster